Interview with René Haaijer

About René

René is running his farm and contracting business ‘Loonbedrijf Haaijer’ together with his father. They are specialized in onion farming. Contracting work is their core business, but they also farm 80 hectares themselves.

Located in the far northeast of the Netherlands they farm on quite variegated soil, but not that extreme, René says. Even though he grew up on the farm, he has only been farming for 5 years. René noticed his soil differences. I see the different needs of our plants, I want to anticipate that.

“It makes no sense to spray variable rates at boomwidth, if I vary it needs to be precise!”.

It is their second season of spraying with LeapBox. With LeapBox they spray applications based on task maps and still do ‘blanket spraying’ as well. The onions grown on their farm are exported all around the world.

Farm Facts

Haaijer

LeapBox since spring 2021

Contractor

Farms: 80 ha

Sprays: 700 – 800 ha per year

Sprayer: Trailed

Brand: Amazone UX

Boom: 40 meters / 50cm nozzle spacing

Crops: Onions, Parisian carrots, sugar beets, cereals

Soil: Sand, peat

Location: Veelerveen, the Netherlands

Why did you choose for LeapBox?

We were looking to upgrade our sprayer. For our acreage, it would not make sense to buy a new sprayer. Our sprayer is ten years old. Technically it is still working fine, but we want to be ready for the future. We need to be able to meet future legislation and we want to move forward.

Improve our spray quality

We want to move forward and spray based on task maps. At the same, we still want to spray traditional too. With LeapBox we have that option. We still spray over half of the applications ‘traditionally’ or ‘blanket spraying’, but our spray quality strongly improved. This is most visible while taking off, slowing down, and cornering.

Capacity – no need to reduce your speed

The constant pressure ensures high spray quality. LeapBox adjusts to speed and maintains the droplet size you select. That used to be the other way around. I would adjust speed to maintain the right application volume and droplet size. Also, we would slow down so you could ‘plus’ a little here, ‘plus’ a little extra there manually. Just to make sure everything is covered. With LeapBox I always have the right droplet size, volume, and coverage. I don’t need to slow down for that.

“There are less skilled workers available in the business, so you become more dependent on technique”.

Spraying runs

While spraying we are dealing with quite some runs. When nozzles jump on or off it influences the pressure. That used to be a problem. The sprayer was continuously trying to adjust the pressure, but it could not keep up and we would have to reduce speed. That’s different now. The system adjusts so quickly now, that it doesn’t affect my spray quality anymore.

We can do both

Currently, we can spray 56 sections with our 40-meter boom. Soon with LeapCat added to the system, we bypass the GPS and each nozzle will be a separate section. I will be able to spray smaller blocks, using task maps. But I like it that conventional “blanket spraying” like we were used to is also still possible, but now with higher spray quality!

How do you experience spraying with LeapBox?

You get used to it quickly. It’s also not that difficult, you don’t need to have an academic degree for it, haha! I mean it’s pretty straightforward. You just enter the l/ha and your preferred droplet size and you are ready to go. It’s high-tech but easier to use.

Generation proof

At first, we were a little bit concerned. LeapBox is a high-tech system that you’re installing on your 10 years old sprayer. However, that turned out very well. I did the first 4 – 5 spray rounds, but then my father took over. He’s now doing most of the applications and is fully comfortable with it. Just like it used to be. Sometimes he lets me get a turn as well.

Nozzles

The first time you see the system spraying it looks and sounds different. I mean, spray with a coarse 08 nozzle? We haven’t done that before and then you start to spray agents you used to spray with a 025 nozzle. That’s quite a difference. The spray quality is not affected by it because of the pressure and electric valves it’s much better! A bonus to it is that your nozzles don’t get clogged anymore.

Modular

LeapBox is a modular system. In the future, we can easily upgrade with new features and developments. Also, if I want to change my nozzle spacing from 50cm to 25cm it would be possible. Of course, it will be a little bit of work, but it’s possible.

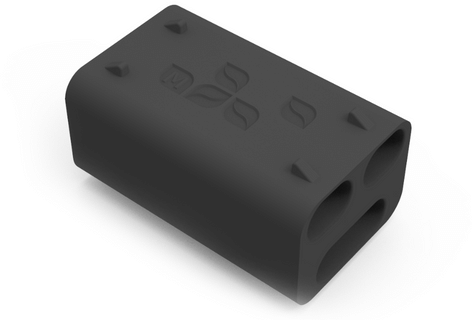

Image: module that controls the valves. LeapBox can control 250 spraying positions.

Why do you want to spray variable rates?

Our soil

We farm on variegated soil with sand, sand with peat, and loam. We are on the low side of variation. It is light sandy soil, not heavy soil or clay. The weed pressure is high. We have a lot of sandy ‘hills’ with low humus levels. Crops are having a hard time growing there, leaving a lot of space for weeds to grow. Due to intense cultivation, it wasn’t always possible to keep it clean, and honestly, we don’t have the products to our availability either.

Is this why you want to farm on plant level?

Yes, that’s exactly why! You don’t want to bother the less vital crops. You want to bother them as little as possible. At places with high humus levels, where a strong and vital crop grows along with a high weed pressure I want to apply a little more.

Future plans

Real-time “tile size” spraying

We want to spray real-time at “tile size” level. We only want to hit the volunteer plants and leave the crop alone. We are specifically looking forward to spraying volunteer potatoes in onions and in sugar beets.

Modular & future ready

The system is ready to meet new legislation. LeapBox is a modular system and if I want I can always upgrade the system to 25cm nozzle distance. It would be a bit of work, but it’s possible. In the future, I have the possibility to extend the system with new technologies such as a cameras and a direct injection. Eventually, I expect a 100% drift reduction from this system. That doesn’t need to be next year, but I’m sure it will come.

Variable rates

Our initial focus is on reallocating herbicides at variable rates based on soil data. In the first season, the base remained at spraying 100%. So, if I want to spray a liter of agent, we will still spray that on average. We were reallocating by varying between 80 – 120%. In the spots where we don’t need it, we spray 80% and where we can use a little extra 120%. The average remained 100%.

Tweaking with buttons

This year we are taking it a step further by varying between 60 – 130%. Eventually, we want to reduce the liquid we use and I am sure we can. For now, we focus on getting it at the right place at different rates.

René Haaijer’s experience at a glance

- Better spray quality

- Higher capacity

- Always perfect pressure

- Easy to use

- No clogged nozzles

- Work with task maps

- Corner compensation

- Ready for the future