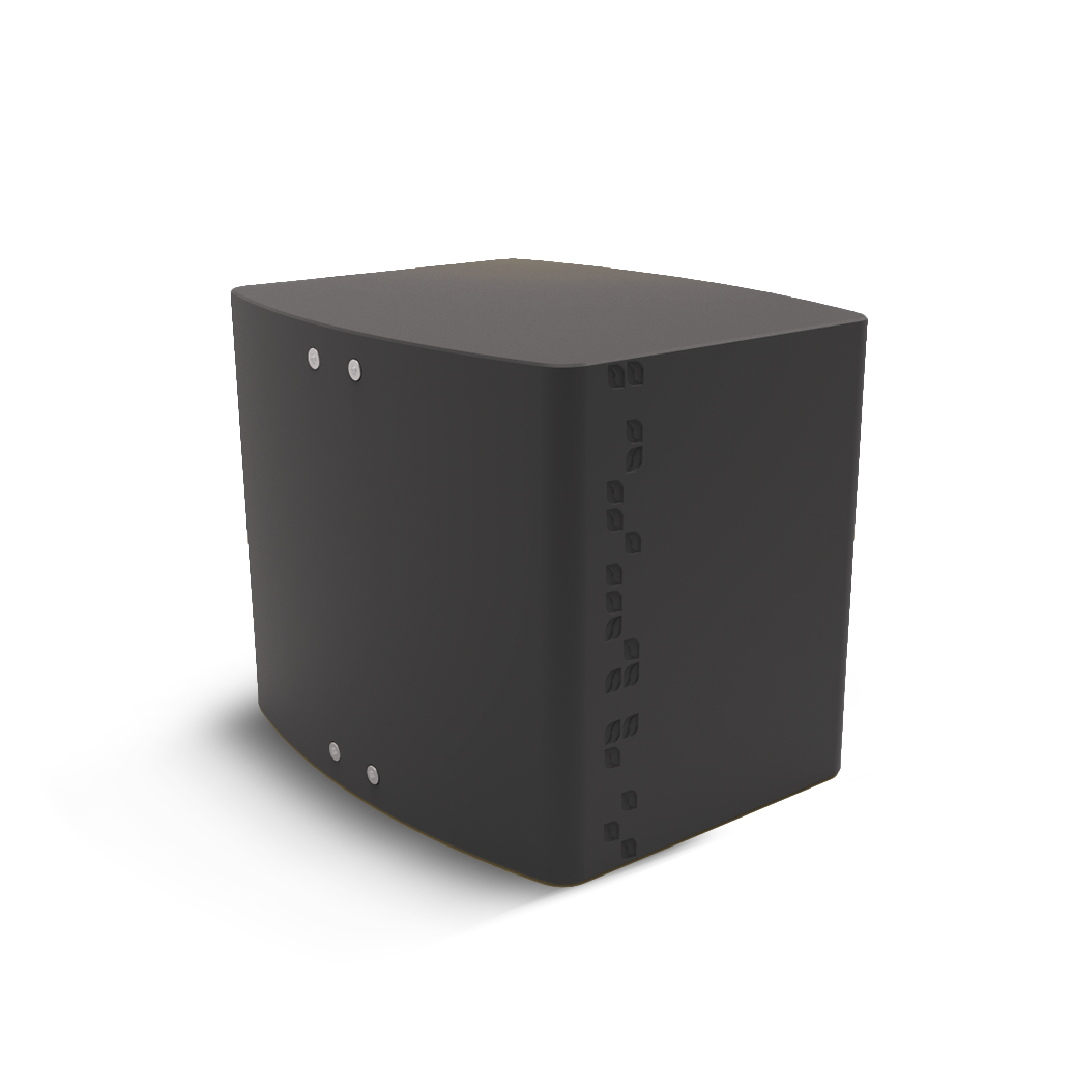

LEAPBOX

The Heart of Excellent & Plant Precision Spraying

WHY CHANGE THE WAY WE SPRAY?

Imagine if every plant could tell you exactly what it needs. Some require more, others less — just like people. But in agriculture, most spraying is still done at field level, (trying to) treate every square meter the same.

At BBLeap, we believe it’s time for a leap forward. We call it:

Farming at Plant Level.

That’s why we developed LeapBox – the technology that makes it sure eliminatig risks via Excellent Spraying and the technology that makes it possible to give each plant exactly what it needs, when it needs it – Plant Precsion Spraying.

Spraying Perfected, Plant by Plant

CONVENTIONAL SPRAYING:

WHAT’S THE PROBLEM?

Traditional spraying systems try to apply products evenly across the field – so regardless of plant size, density, or health. But conditions constantly change:

- Speed variations (start, stop, turning) affect pressure and dosage

- Manual nozzle switching is inflexible and error-prone

- Overdosing and underdosing are common in corners and curves

- Uniform treatment leads to waste, crop stress, and lost potential

In a world where efficiency and sustainability matter, this method simply falls short.

PWM SPRAYING:

A STEP FORWARD, BUT NOT THE LEAP

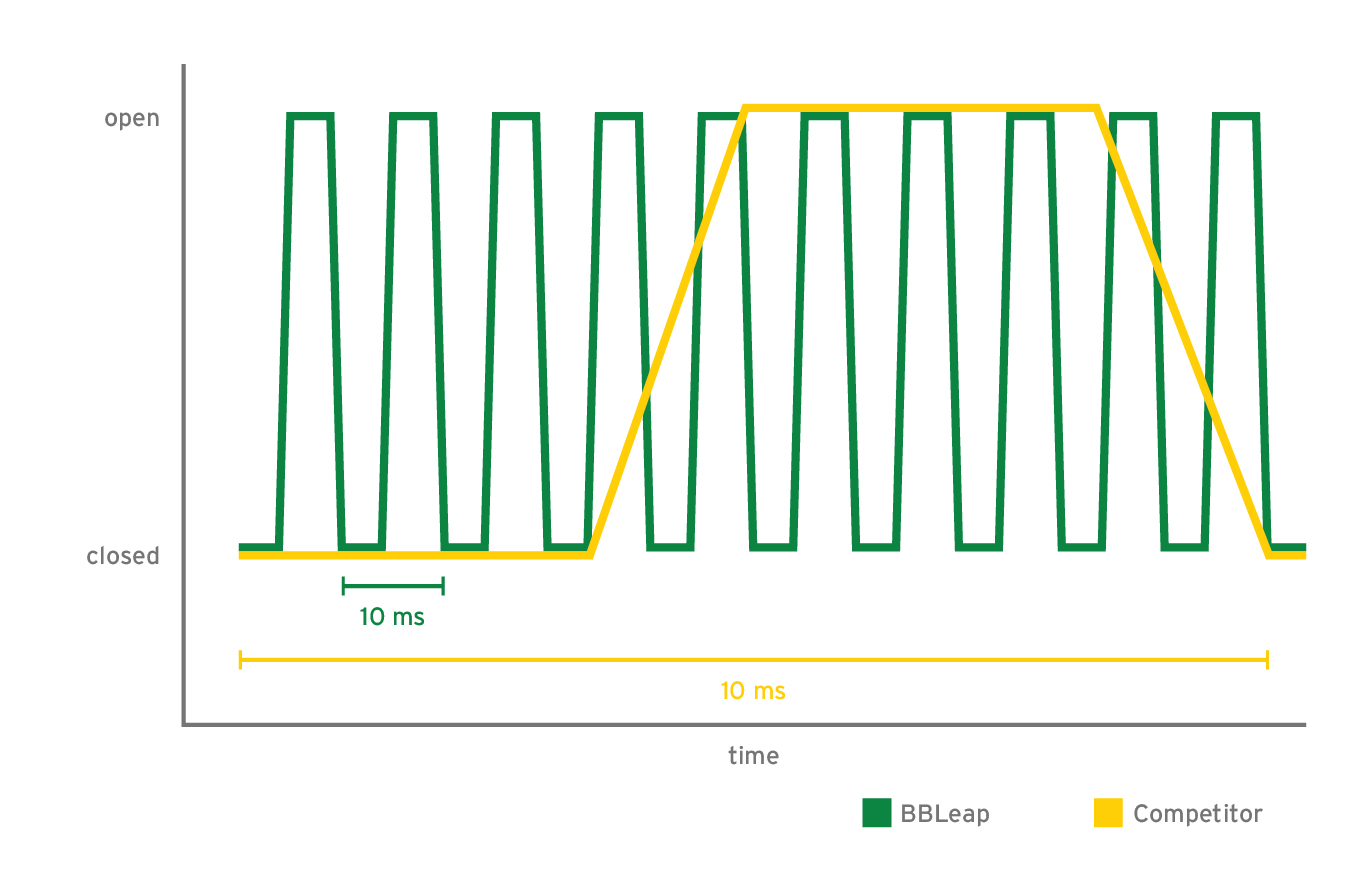

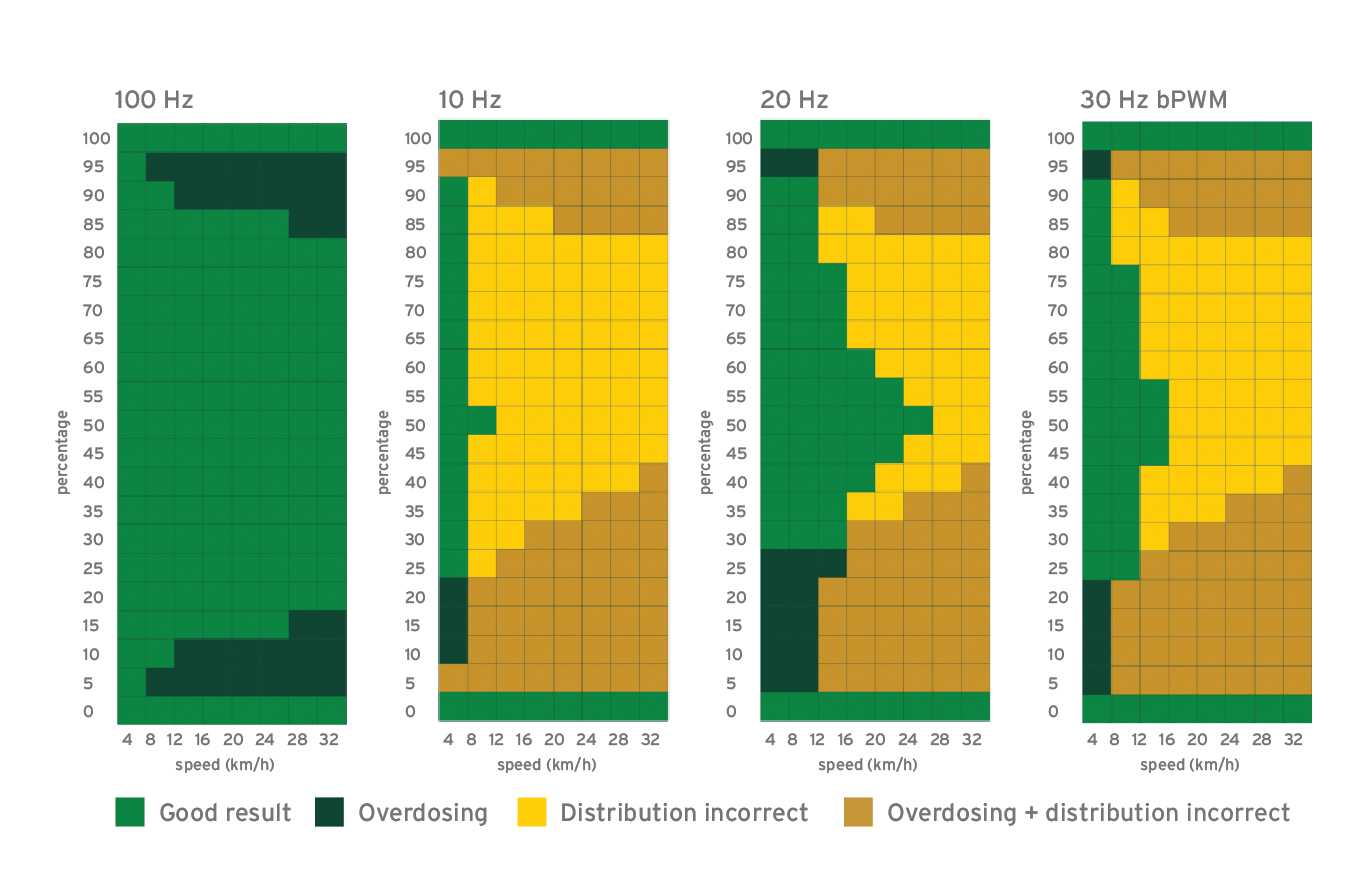

Pulse Width Modulation (PWM) was introduced to regulate application rates more flexibly. But even PWM has limitations:

- Slower switching speeds limit response accuracy

- Droplet sizes vary under changing pressure conditions

- Distribution issues remain in turns, on slopes, or at varying speeds

- Rate flexibility is still restricted, especially at high speeds

PWM is progress – but not the final answer.

LEAPBOX: EXCELLENT SPRAYING, PLANT PRECISION SPRAYING

LeapBox is the only system on the market that solves all of the above challenges. We reimagined spraying from the nozzle up, creating a modular, high-frequency control system that minimizes risk, 100% accurate spraying and allows real-time, plant-specific application with no compromises.

ALWAYS THE

PERFECT SPR Y

Y

QUALITY!

HOW LEAPBOX WORKS

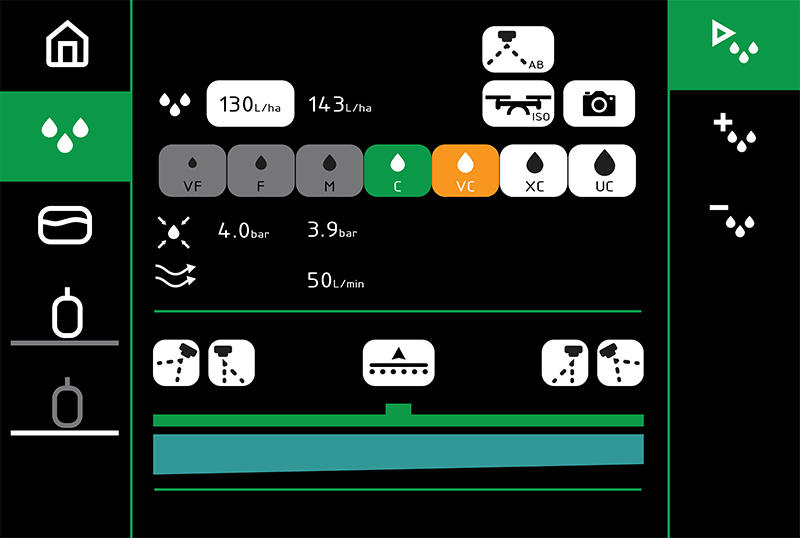

Variable Frequency & Duty Cycle

Unlike traditional PWM, LeapBox operates at up to 100Hz, enabling:

- Extremely fast open/close times

- Stepless control from 2% to 98% at low speed

- Consistent spray pattern at any speed – even up to 36 km/h

Nozzle-by-Nozzle Control

Every nozzle becomes its own smart sprayer, adjusting output in real time based on:

- Speed

- Turns

- Crop location

- Task map input

- Even tree contour or plant structure

Full System Integration

LeapBox connects with LeapSpace (data input & control platform) and is ready for:

- High-resolution task map execution (25×25 cm)

- Real-time spraying with LeapEye cameras

- Spot & pattern spraying

- Tree profile applications

- Data logging & as-applied maps

WHAT YOU GET WITH LEAPBOX

100% Accurate Spraying – Always the right dose

No Nozzle Switching – One nozzle for every crop & condition

Speed & Curve Compensation – No more under- or overdosing in turns

ISOBUS Compatibility – Seamless integration into existing systems

Zero Waste – Use less input, grow more yield

LeapBox is already boosting performance on hundreds of sprayers — both new and retrofitted — around the world.

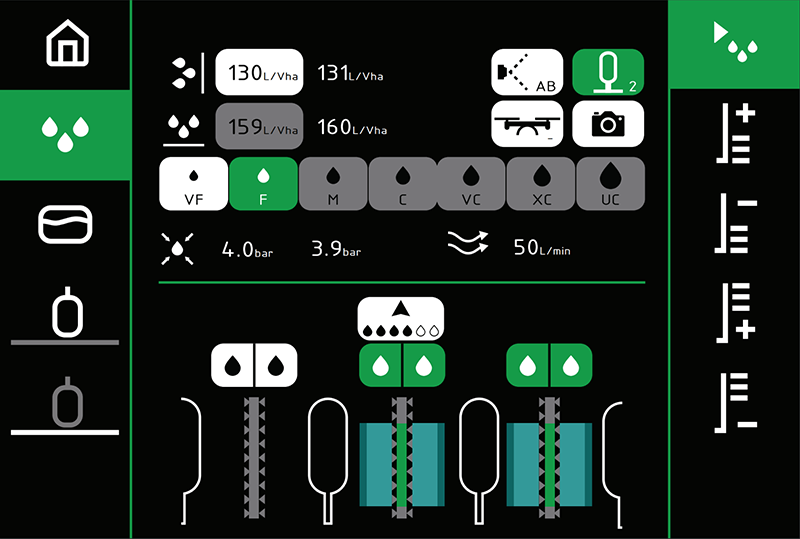

FROM BROADACRE TO ORCHARDS – AND ROBOTS TOO

LeapBox is fully compatible with all sprayer types and brands:

- Broadacre sprayers

- Orchard sprayers

- Robotic & autonomous sprayers

Install it on your current machine or go for a factory-integrated LeapEdition sprayer with one of our OEM partners.

LEAPBOX = THE FOUNDATION FOR SMART FARMING

Once installed, LeapBox becomes the gateway to:

Plant Precision Spraying – powered by task maps

Real-Time Spraying – with AI and camera-based detection

Field Insights – with as-applied tracking and cloud integration

One system. Infinite precision.

TECHNOLOGY INSIDE LEAPBOX

Engineered for Precision. Built for Every Sprayer

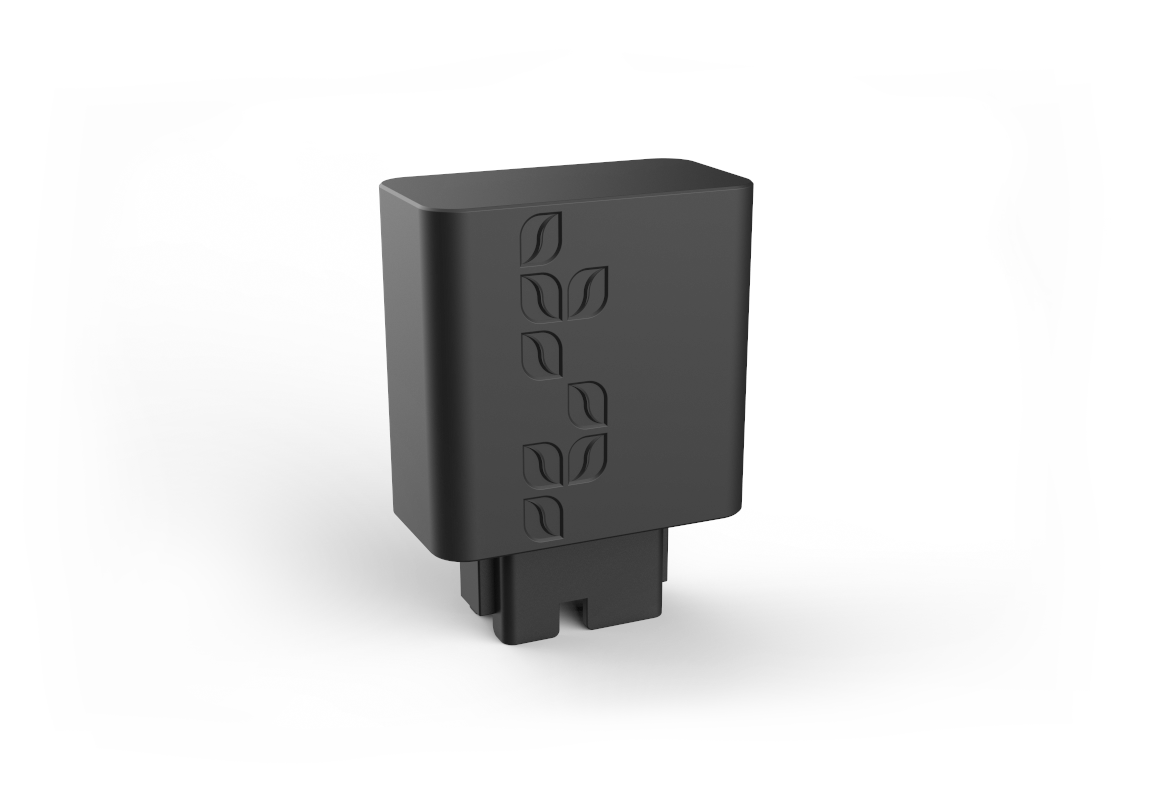

Key Components:

- LeapCore Control Unit – The powerful processing unit at the center of LeapBox, enabling real-time plant-level spraying decisions.

- Variable Frequency Valves – Ultra-fast solenoids regulate application rate per nozzle, achieving 100 Hz spraying accuracy with minimal delay.

- BBLeap Modules – Control each nozzle individually for variable rate application with unmatched precision.

- 48V Power Supply – Ensures the fastest valve response time, maintaining ideal droplet size at every speed.

- Integrated IMU (Gyroscope) – Detects boom angle and movement for automatic turn compensation and curve control.

- ISOBUS Compatibility (VT/UT) – Seamless integration with existing terminals for easy, intuitive operation across all sprayer brands.

- Cabling & Converters – A complete wiring package with CAN-bus communication and 4G connectivity for smooth system performance and remote support.

Fits every sprayer. Ready for every challenge.

From broadacre to orchards, LeapBox adapts to your machine — empowering you to spray smarter, faster, and with total control.

READY TO LEAP AHEAD?

Retrofit your existing sprayer

Equip your new sprayer withLeapBox

Experience the future of plant-level spraying