Timmermans Agri Service

Interview

With a passion for crops, the company was founded in 1989 by brothers Harm and Gerton. It was when the brothers realized they were getting positive energy from unburdening their customers, that Timmermans Agri-Service began specializing in environmental and crop care.

Youri Timmermans, 2023

Brothers and founders Gerton and Harm Timmermans, 1989

How Timmermans transforms agriculture

Removing foliage in potatoes

Timmermans highlights the transforming impact by integrating the BBLeap system to their operations. The technology has the ability to execute variable task maps. This produces remarkable results when it comes to optimization and environmental sustainability.

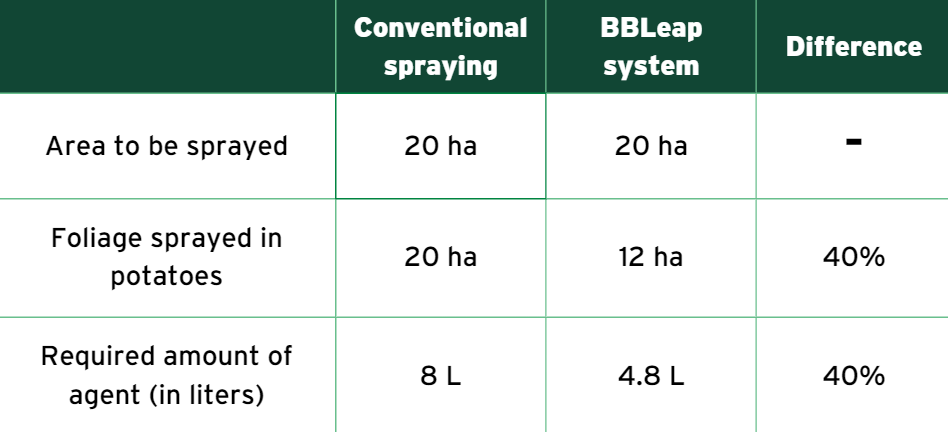

Timmermans is enthusiastic about the successful use of BBLeap on foliage removal in potatoes. 40% of his potato field was not sprayed because there was no foliage left. Where foliage was present, it was treated variably.

Through a 40% reduction, this approach results in the promotion of environmentally friendly practices, which is essential in today’s agricultural sector.

Want to find out how Timmermans achieved these positive results?

Case: variable removal of foliage

Foliage removal – variable spraying based on biomass

- Plot size: 20 hectares of potatoes

- Spray purpose: To remove foliage in potatoes

- Input: Biomass data collected via camera sensors on 39 m wide of 2 m x 2 m

- Execution: high-resolution 25 cm x 25 cm task maps

In this field

- 8 ha of potatoes remained untouched and 12 ha of potatoes were sprayed variably

Result

- Complete foliage removal while 40% of the plot was not sprayed

Impact

Timmermans did not need to spray 40% of the plot, since there was no foliage. That contributes significantly to sustainability. The best approach is to just use what you need. Therefore, applying the right amount at the right place is the solution. It is ideal that that is now possible with this technique. With BBLeap, he reduces environmental impact and leaching of application residues into surface water, extending his impact beyond just the agricultural sector.

- 40% less spray application

- Lower cost of agents

- Lower environmental impact

- Implementation of sustainable cultivation practices

- Focused on the specific needs of each plant

“Things are changing in agriculture, precision is becoming the new norm and BBLeap is the solution to that.” – Youri Timmermans

Factsheet

Configure your LeapBox now

A retrofit is possible for nearly any type and brand of sprayer. Read more about

the possibilities of Farming On Plant Level with your sprayer.