In modern agriculture, precision is increasingly important, and technology plays a key role in this. Gerben, an enthusiastic BBLeap user, shares his experiences with the combination of drone technology and BBLeap spraying technology.

Farm Facts

Eendracht Agro

Location: Zuid-Beijerland, Zuid Holland, the Netherlands

Company: Eendracht Agro

Crops: Potatoes, onions, beets, grass seed, spring wheat, winter wheat and barley

Hectares: 320

Functionalities: Leapbox

Sprayer: John Deere

‘With one drone flight and some data analysis, I save 250 euros per spray, which ultimately saves me 2,500 euros if I apply it to multiple plots.’ – Gerben Melissant

From drone flights to savings

Gerben works with an RTK drone combined with BBLeap to spot spray weeds. By making drone flights of about 15 minutes, he collects some 2,500 photos that are compiled into one large overview of his field. This allows for precision in spraying, treating only the weeds and not the rest of the field. This has resulted in impressive resource savings of 94%. ‘With one drone flight and some data analysis, I save 250 euros per spray, which ultimately saves me 2,500 euros if I apply it to multiple plots.’

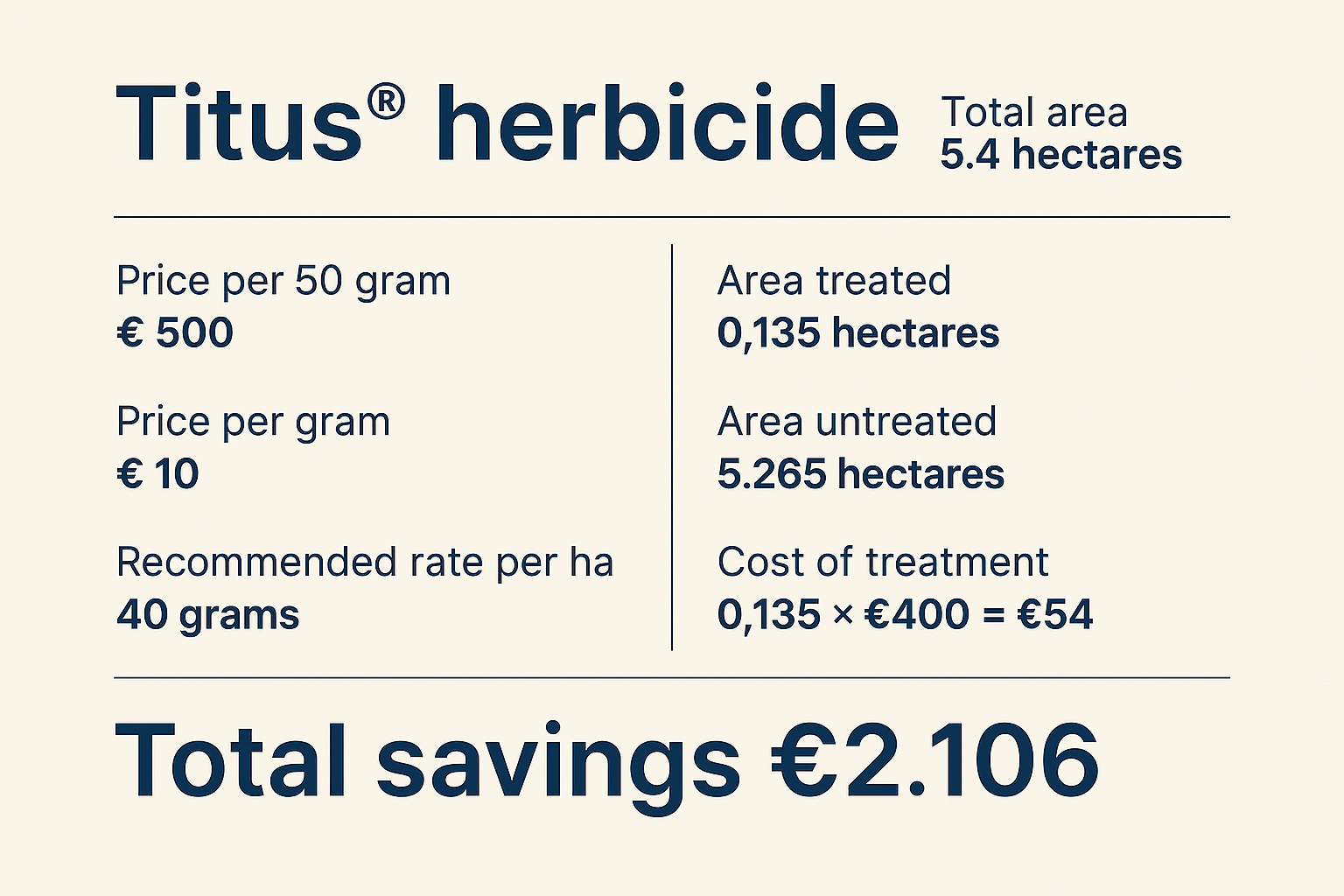

User case Titus in potatoes

At Eendracht Agro, precision spraying with BBLeap technology and Pix4D drone data led to significant cost savings in herbicide use. By treating just 0.135 hectares of a 5.4-hectare potato field with Titus®, Gerben saved €2,106 while crop growth remained unhindered.

This case study shows how targeted spraying reduces input costs and supports sustainable agriculture.

Innovation with BBLeap

Using BBLeap to regulate dispensing per cap enables targeted and efficient application of agents, which is crucial in weed control. ‘With BBLeap, I can regulate my dosage per nozzle and spray agents only where it is needed,’ Gerben explains. Gerben emphasises that the system shows its strength especially in applications where variable dosing is necessary.

‘With BBLeap, I can control the dosage per nozzle and spray agents only where it is needed’ – Gerben Melissant

The advantages of variable rate spraying

Gerben explains that for him, BBLeap’s variable rate function is very important, for example when spraying against Phytophthora in potatoes. ‘In the first two sprays, you only need to use two-thirds of the pesticide because the plants are still so small.’ If you open your caps then, with any other spraying technique, you would just spray a lot of pesticide on the bare soil. That’s just a waste!’ Thanks to BBLeap, the caps that would otherwise spray on bare soil are turned off. This ensures that Gerben needs to use a third less pesticide, which both saves costs, but more importantly, also contributes to better crop growth.

‘Because I spray less pesticides on the soil, fewer onions fall away on the lighter soil and grow better. Not only does it save costs, but it also increases yields, which contributes to a better return.’ – Gerben Melissant

Cost savings and crop improvement

Gerben emphasises that the large areas of sand in the plots, combined with the variation in soil types in their region, affect the effectiveness of soil herbicide use. ‘We are in Goudswaard, a very old polder that was reclaimed in the 13th and 14th centuries,’ he says. The plots were divided and farmed in 15 different ways until the land consolidation, leading to many differences in soil type per plot.’ This variation in soil types, such as sea clay and river clay, means that some parts of the plots are more susceptible to resource loss than others.

Using BBLeap helps Gerben manage these variations effectively and use resources more efficiently.The technology not only makes the savings obvious, but also has a positive impact on the crops. For example, Gerben sees onions growing better due to more efficient use of soil herbicides. ‘Because I spray less pesticides on the soil, fewer onions fall away on the lighter soil and grow better,’ he says. ‘Not only does it save costs, but it also increases yields, which contributes to a better return.’

In addition to regulating the output per cap, BBLeap also offers the ability to adjust the droplet size in the system. This is a big advantage over traditional systems, where farmers often have to change the caps manually, depending on the type of spraying. Gerben explains: ‘In onions, for herbicide sprays, you want to use a coarse droplet so that the pesticide settles well on the soil and doesn’t blow away. For fungicide sprays, on the other hand, I choose a fine droplet because it penetrates the crop better.’ Thanks to BBLeap, he can now easily adjust the droplet size without physically changing the caps, saving time.

Improved spray precision and drive-off with BBLeap

With the previous spray technology, Gerben had to deal with a corrective pressure setting while driving. If he drove slowly, the pressure dropped, resulting in a lower release of the pesticide. When he drove faster, the pressure increased and the release was higher. Especially in fungicide sprays, where lower pressure resulted in a less fine droplet, this affected the effectiveness to the detriment. ‘You saw especially with fungicide sprays that when you drove away, the first few metres were less successful because the pressure was lower and the droplet size less fine.’

These fluctuations in pressure and release caused irregularities in the treatment, which was especially visible in the corners of the field, where the speed and pressure changed. This often resulted in diseases such as Phytophthora spreading more easily… Gerben explains: ‘You often saw more disease in those first metres due to underdosing, because the pressure was not set properly and the droplet size was not optimal.’

With BBLeap, that problem is solved. Thanks to the system, the dosage is always consistent and optimal, even when driving away. ‘Now you can drive off and you’re actually sure that the pressure is right and the dispense is correct,’ he says. This ensures that the pesticide is evenly distributed, which not only increases effectiveness but also reduces the risk of diseases such as phytophthora. Gerben noted that last year he was able to control the problem of under-dosing and the associated disease spread.

‘In fungicide sprays, you used to see that the first metres were less successful due to lower pressure and larger droplets. With BBLeap, the release is now always consistent, even when driving off and cornering.’ – Gerben Melissant

Looking towards the future

Gerben is excited about the future possibilities of this technology and sees a lot of potential. ‘In the coming years, I want to further explore the possibilities, especially in terms of variable application of agents with higher or lower doses.’ What he particularly appreciates about current technology is the ability to set everything in advance and make quick adjustments if necessary, such as excluding certain areas from spraying.

The future of precision agriculture

Gerben believes the future of precision farming lies in further developing and improving systems like BBLeap. It offers the opportunity to increase farm efficiency while reducing costs. ‘If I continue like this, I think I will have the technology completely paid for itself within a year,’ he says. ‘And that is without a doubt a big step forward.’

BBLeap provides a powerful tool for Gerben and other farmers to improve the efficiency of their operations, cut costs and ultimately increase profits. Combining drones, precision technology and smart systems like BBLeap not only helps to optimise spraying, but also to make farming more sustainable.